Varminter Model - $230.00

Designed to reduce the gunshot noise of .22LR and .22 Magnum rimfire rifles, and safe to use with both subsonic and HV ammunition. This unit can also be used with very small centrefire cartridges such as .22 Hornet – and sub-calibre derivatives such as .20 Hornet, .17 Hornet, plus the 17 HMR and .17WSM, etc.

( NOT FOR .223Rem, .204Ruger, .222Rem, .221 Fireball, .17Rem, etc. )

The Varminter™ model is a high quality, hybrid combination of 6000 series aluminium, 300 series Stainless Steel, and Grade 9 Titanium. All external parts are finished to a high standard and are black anodised for protection, in a matt (non-glare) finish. It features CNC machined stainless steel spiralled muzzle brake, as well as 5 stainless steel mid-baffles and a titanium slave tube in the primary expansion chamber section – thus providing outstanding durability and strength but in a relatively light and compact package. The Varminter™ can be dismantled for cleaning by the shooter – an extremely important feature.

No springs or loose baffles or spacers to worry about, and no problems with reassembly or baffle misalignment – anyone who is reasonably competent mechanically can clean and service this suppressor themselves. Why waste your money on a low-quality or permanently-sealed rimfire suppressor? To maintain optimum performance, most rimfire suppressors should be cleaned every 300-500 rounds (or as required) – especially if using a lot of cheaper brands of .22LR subsonic ammo – to remove any excessive powder/lead fouling build-up.

There are many other rimfire suppressors on the market that claim to be easily dismantled – this may appear so when they are new and clean – but not in reality once the unit becomes dirty, corroded, or the powder fouling has set like concrete and locked everything up solid. The Varminter is designed in such a way that the outer tube is essentially just a sleeve/vessel to hold all of the internal components together and in perfect alignment – the dirty propellant gases and fouling are retained on the inside of these internal parts so that the gas and carbon/lead/powder fouling never comes into contact with the inside of the aluminium tube, so there is no way for the unit to become seized up.

- There is also a special .17cal-ONLY version available, specifically for use on the .17HMR, .17WSM, or .17 Hornet cartridges, and the mid-baffles feature a smaller Ø5.6mm clearance hole just for the .17cal bullet. This .17cal model must NOT be used with .22cal or .20cal.

(A special Takedown Tool for the front end-piece (6-pin socket) is available for purchase separately, if required. The tool is not included with the suppressor as standard. The removal tool will fit both the .22cal and the .17cal-only front end-pieces, so if you own both units you will only need the one removal tool. )

Note: As with any suppressor, this unit will not fully silence High-Velocity (supersonic) ammunition. No suppressor in existence can remove the super-sonic crack of a bullet breaking the sound barrier. True silenced performance is only achieved with subsonic .22LR ammunition. (Velocity must be below 330 Metre/sec, or 1050 Feet/Sec.)

TECHNICAL SPECIFICATIONS

- 6.7“ long (170mm), 221 grams, Ø1 ¼” (Ø 31.5mm)

- Calibres: .22LR, .22Mag, .22 Hornet, .17HMR, .17 WSM, .17 Hornet

- Special model available specifically for .17cal only, for even better suppression effect.

- Thread options: ½ – 20, ½-28, M18x1.0mm. (These are the current thread options. Others may be available in future, or by custom-request. Very concentric and close/tight spec threads – this may cause fitting problems with some pre-threaded barrels, especially if the male thread has been cut slightly oversize previously to match another brand/model of suppressor. We recommend that for best results it may be necessary in some cases to have your barrel custom-threaded by a gunsmith to fit and match the female suppressor thread precisely. )

- Removable baffle-stack system, with o-ring buffers, generates excellent turbulence/suppression effect. Precision-machined from solid 303 stainless steel barstock – Unique design is the result of extensive testing, and tests show significantly better performance than some competitors much longer and heavier rimfire suppressors. We have tried to remove as much mass as possible from the stainless baffles in order to keep the overall weight down, while still maintaining strength and durability.

- Replacement baffles are available for purchase in the event of damage, or any excessive wear developing due to very high volume of shooting, or commercial use. In most cases though, these stainless baffles will most likely outlast a lifetime of recreational use with rimfire ammunition.

- 100% Designed and Made in New Zealand.

- Price (at APRIL 2023): $230.00 (incl GST). Fitting costs (if required) are additional.

No Export Sales – all sales are for domestic NZ only.

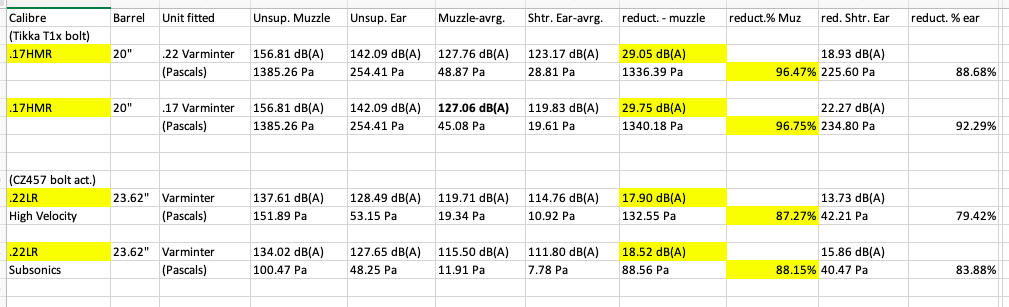

Sound Test Data:

Explanation of Sound Test Results

In the test data above we used a .17 HMR rifle with 20″ barrel, fired 6 shots unsuppressed, 6 shots with a varminter suppressor with ’17cal’ baffles installed, and 6 shots with a varminter suppressor with ’22cal’ baflles installed. The averages of those shots (and also combined the left and right ‘muzzle’ and the left and right ‘shooters ear’) are listed above.

The interesting thing here is that you can see the ‘milspec muzzle’ readings for both the ’17cal’ and ’22cal’ baffled suppressors are about the same – just over 127dB, but the ‘at ear’ readings are different by about 3.34dB, which is significant. Remember this is the exact same ammo used, on the same day, same rifle, just different clearance hole sizes on the suppressors used.

What is actually happening here is that the sound meter/mic is picking up the sonic crack of the bullet, which in this case appears to be right on the 127.06 dB mark, as being the highest (peak) noise at that location. From the results, and you can safely assume from calculations, that the actual suppressor/gas noise from the ’17cal’ baffles suppressor is more likely to be about 124.42dB. (which would essentially mean a dB reduction at the muzzle (due to the suppressor) of about 32.39dB, which is a good and solid amount of sound pressure peak reduction of about 97.6%). To prove this we would need to repeat these tests with a laboratory-grade system (like the B&K ‘Pulse’ system), but the American test data we have seen confirms this phenomenon where – once you get to the point of extreme sound suppression for a specific calibre – you have recorded sound peaks for the sonic crack of the bullet itself, which can be higher and different than the peaks for the actual gas noise from the suppressor.

This video from YouTube explains and shows their graph example of the sonic crack peaks in relation to the gas noise peaks, which is good to see. However, when they talk about deliberately manipulating data to remove bits that they don’t think are relevant, this can raise ethical issues about what you trying to do or convey. In the real world the sonic crack peak is still there, so if that is the loudest noise then that’s what it is. This does show you however that when you get big enough or effective enough with suppressors, that there is a point of diminishing returns, and there is no point making the suppressor any bigger, longer, or heavier than is required. (This is one reason why full-length over-barrel suppressors have fallen out of favour now.)

Note also that with some subsonic bullets of .30cal or larger diameter, the pressure spike (‘Schlieren’ effect) off the bullet ogive is picked up by the ‘milspec muzzle’ mics – even at subsonic velocities – and this is why with the .30cal and larger subsonics the muzzle readings may not get below about 126dB, whereas with the ‘at ear’ readings you will see more of a realistic representation of the performance of the suppressor.