Suppressor Sound Testing

1. Introduction:

Any product that goes through the stages of design, development and manufacturing must also be subject to some degree of testing to ensure that it is not only safe, but that it works effectively at it’s intended task. Testing of firearms suppressors (for sound levels) has always been difficult to undertake due to the very short duration of the peak sound-pressure level (SPL) curve of the gunshot blast. Accurately measuring and capturing readings for these peak sound levels (at extremely high levels, and especially over 160 decibels) has for decades been out of the reach of the average firearms reviewer/writer, or enthusiastic firearms owner who just wants to know how quiet his silencer/suppressor really is. Even a lot of laboratories or professional audiologists in this country don’t have the sound testing equipment required to accurately measure gunshot peak SPL’s, so as a result you often get tests done with substandard equipment which generate inaccurate – and in some cases grossly misleading – sound level readings which are then disseminated (often online, but sometimes in published magazines) to others who may also be misled into believing this false data. With the common use of ‘smart-phones’ now, or other cheap hand-held sound level meters, these are two of the most common sources of misinformation in relation to gunshot SPL testing.

2. Equipment used:

Mil-Std-1474D (US Dept. Of Defence) has for decades been the guiding standard/document used by most of the international firearms community for testing protocols in relation to sound pressure levels of hand held and shoulder-mounted firearms. This standard has very precise requirements for the sound level meters and associated equipment (microphones and cables, calibration equipment, etc.) to be used, as well as the placement location of the special microphones in order to capture readings from standard reference positions.

One of the main requirements for the sound level meter is that it must be able to capture and hold peak sound level impulses with a response time (or ‘rise time’) of 20 microseconds or less. (20µs = 20 millionths of a second). The sound level meter – and the special pressure microphone used – must be capable of reading up to about 172dB SPL for centrefire firearms, or up to 196dB SPL for explosives or fireworks. For digital meters the sampling rate of the meter/processor must also be 196,000 Hz (196 kHz), or greater.

The significant problem here for anyone wanting to undertake credible sound level tests on firearms is that most of the hand-held commodity-grade meters used for domestic or commercial acoustic measurements only go up to about 130dB, and the response rate (or ‘rise time’) is far too slow at 0.1 millisecond (100µs), or slower. The digital sampling rate of 48,000 Hz (or lower) is also no good for testing of very short duration gunshot impulse/peak noise levels.

Proper sound pressure level meters for testing gunshots are very expensive, and are not commonly available. The only sound level meters than can accurately and consistently measure gunshot peak sound pressure levels (in accordance with MIL-STD 1474D) that are still currently accepted in the industry for this purpose are the older analogue type meters such as the legendary Bruel & Kjaer 2209 (which reads up to 170dB) or the old Larson Davis 800D (which reads up to about 140dB, but can be modified to go up to 160-170dB with add-on equipment). The only newer meters that meet the spec are the Bruel & Kjaer ‘PULSE’ system – which is a full laboratory-grade system that requires mains power to run (which limits it’s portability), or a similar system put out by National Instruments (though at the time of writing it is uncertain if that is still available or has been discontinued). These more modern systems are VERY expensive to purchase, to set up and maintain, and often have annual licensing fees for the software as well. These significant costs ($40K plus, and $10k per year for licensing) certainly limit their use and availability to the industry. Even an analogue B&K2209 system (refurbished/serviced) with ¼” pressure mic, extension cables, field calibrator ‘pistonphone’, and a few other accessories goes for about US$7,000 at some of the specialist Audio equipment dealers in the USA. There are places in the US where you can hire these meters, but in countries like NZ if you need them, you basically have to buy your own.

3. Our Sound Testing Equipment

At the time of writing, we currently have FOUR functioning/calibrated B&K 2209 sound meters (and another two spare meters as well, for parts or as backups). 4x B&K 4136 ¼” microphones, 1x B&K 4938 ¼” microphone (with special right-angle adaptor – for shooters ear left measurement), 1x ¼” 4135 microphone (field type), 4x field-calibrators (124dB and 114dB models), as well as an assortment of leads and accessories, and a few other spare microphones as well, all acquired over the past few years. The accumulated replacement value of all of this equipment would be in the tens of thousands of dollars worth. (The new replacement cost on the B&K 4938 ¼” microphones alone is over NZ$4000+gst EACH). So you can see that once you go down the path of undertaking proper suppressor sound testing it’s not a cheap exercise, and there is always going to be a significant amount of investment required, as well as training and time to get the locations or your microphones and rifle mounting set up just right.

4. ** Equipment that is NOT suitable for testing gunshot sound pressure levels (to MIL-STD-1474D):

- Any smartphone. Reasons: The internal mics are only rated up to 110dB, and the maximum readings generated often max-out at about 105dB. You can get external/add-on mics, but these may only increase the upper limit to 130dB max, perhaps? However, the other problems is that the rise time will be way too slow at over 100µs, or possibly even over 200µs. Sampling rate – unknown, but likely to be under 24 KHz. Smartphones are simply not designed to be accurate sound test meters, and even less suited to testing gunshots. There is also a high chance that you would blow the mic on your phone if you attempted to take mil-spec muzzle readings with it from a centrefire rifle.

- Any common Type 1 sound lever meter, of a retail cost under $4000 (new). (These only usually go up to about 130dB max, and have cheap microphones (usually ‘field’ microphones, not ‘pressure’ microphones). The response time is usually 0.1millisecond (100µs) or greater, and the sampling rate may be in the 24 kHz to 48 kHz range. Many of these types of commodity meters do not have a peak hold function, and built by relatively cheap methods and costs of manufacture, so you are basically wasting ammo even attempting to test .22LR with these type of sound meters.

- Larson Davis 812 sound level meter – has a peak hold function, but rise time is 30µs unweighted, and 60µs ‘weighted’. Sampling rate only 48 kHz. (needs to be 196 kHz). The recording scale on the meter only appears to go up to 140 dB.

- Larson Davis LXT- QPR sound level meter – although being marketed as a meter supposedly suitable for testing gunshots, it does not actually meet the milspec requirements, and has been thoroughly discredited by a lot of suppressor industry professionals in the USA (and Europe), as the readings it produces are often inaccurate and inconsistent, largely due to it’s failure to meet the mil-std-1474D requirements (Rise time only @ 30µs (50% too slow), and sampling rate of only 48 kHz. (400% too slow). Now while it may be ok for testing gunshot ambient noises at a rifle range, or checking loud impulse noises for safety purposes, it does not have the accuracy to properly evaluate gunshot or suppressor noise, and as such any results recorded or published from equipment like this must be viewed as being ‘indicative’ or ‘ball-park’ figures only, and not necessarily accurate data.

4a. Why won’t this non-Mil-std-compliant equipment work?

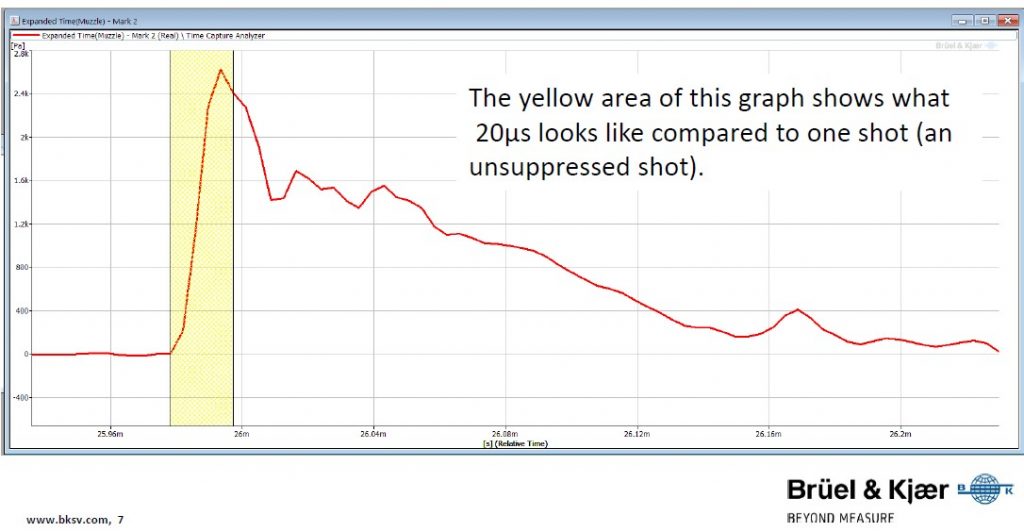

As you can see in the graph above, the yellow area represents a time span of 20µs. Any meter/mic system that cannot measure sound pressure peaks UNDER 20µs will fail to capture the true peak of the waveform, and will end up capturing a reading that occurs some time after the peak has already passed. Same issue with the sampling rate. If a sound meter (like the Larson-Davis LXT-QPR) only has a sampling rate of 48 kHz, that is a sample spacing of every 20.83µs. So you can see that it is virtually impossible for a meter like that to accurately plot a waveform curve and capture the true crest/peaks correctly. In comparison, a laboratory-grade system like the B&K Pulse (with a sampling rate of 196 kHz) will be taking samples every 5.10µs, which is what you can see in the graph above (about 4 readings/samples in a 20µs time span).

5. WHAT DOES THIS MEAN IN LAYMANS TERMS:

Non-mil-spec sound meters/system will tend to record lower dB levels than what the true peaks actually are, and this will tend to produce dB levels (or claimed dB reduction levels) better than what they are actually achieving in practice. Any sound test data that is recorded with equipment that does not actually meet the specs for Mil-Std-1474D, should be viewed with suspicion until it can be independently verified on better equipment. That said, testing gunshots and sound suppressor SPL’s is difficult to achieve consistently due to the changeable nature of the ambient weather conditions. Temperature, humidity and wind, will all have varying effects on the readings and results taken on any given day. And that is why if you are doing comparison tests, you must try to do all of those tests on the same day, with the same equipment, and also checking the equipment regularly for correct calibration, thus ensuring consistency.

(** This section has been included for education purposes only, to try to explain how so many of the online or published ‘sound tests’ of suppressors out there may be very misleading, erroneous, fallacious, and/or disingenuous. )

Table of approx.. conversions (db/Pascals)

Info about sonic crack (bullet schlieren) including subsonics

(skip to 4:55 minute mark to see explanation of bullet schlieren on subsonic bullet. Note that at some point the microphones at milspec muzzle (left and right) will be reading the sonic crack of the bullet even when the actual suppressed gas noise is lower than this. The sonic crack of a bullet can be in the 125 db – 130 db range depending on calibre and bullet velocity.)

OSH limits, other considerations (hunting with a dog, horse, etc.)

Generally speaking, OSH (or OSHA in the USA) set the maximum level for ‘impulse noise level exposure’ for humans in workplace environments at 140dB, but obviously steps should be taken to minimise exposure to noise and high pressure sound levels as much as possible. All of the Kaimai centrefire suppressors tested come in below the 140dB range at the shooters ear location, which is fine for the shooter himself. However, if you are shooting alongside other people of directly over an ‘indicator dog’ (for deer hunting), then one of the larger suppressors that have a longer front section and thus generating SPL readings of below 137dB are obviously going to be a better and safer choice.

Expected readings:

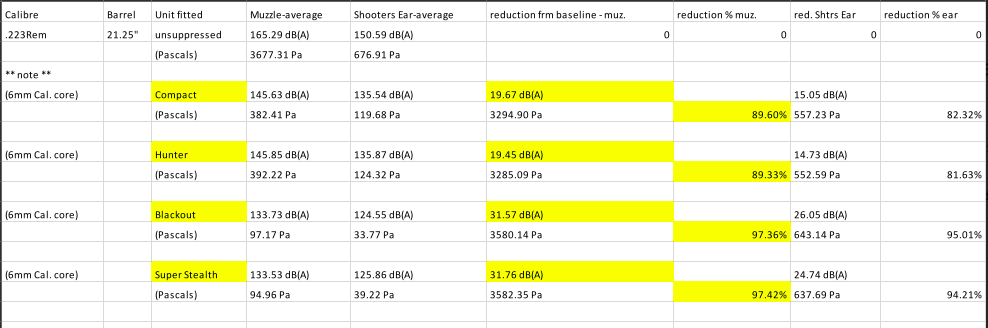

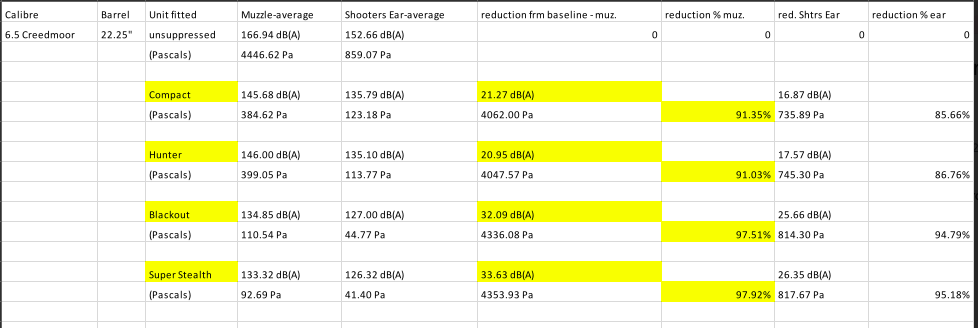

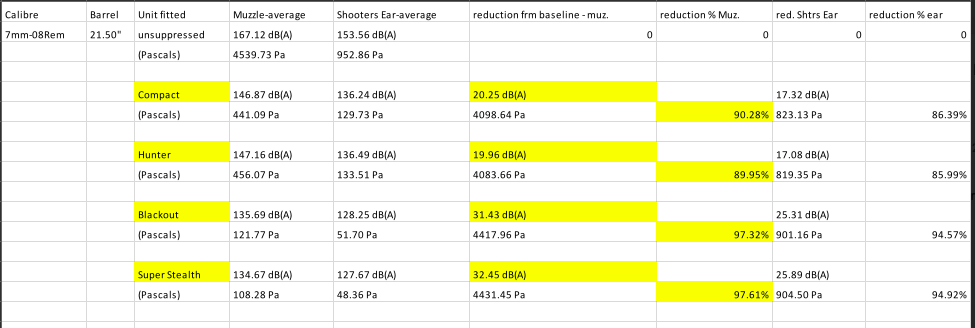

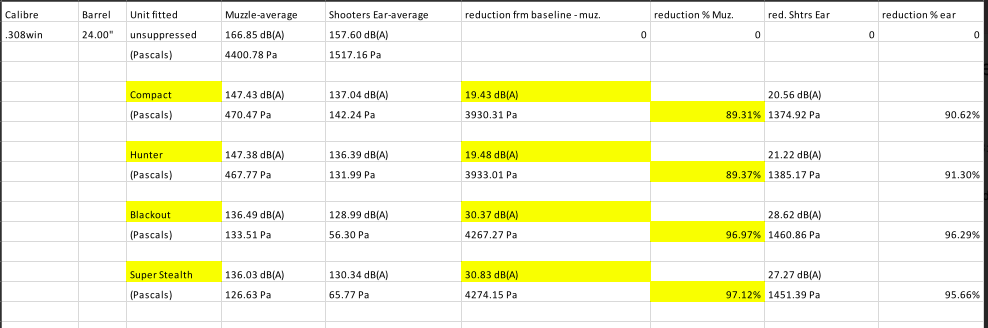

Centerfire suppressors for the NZ market (usually up to 45mm diameter) are mostly of the over-barrel design, with a muzzle-forward section of a minimum of 3.5” to 4” long, or longer in the 6-8” muzzle forward section. (The amount of expansion tube section back over the barrel doesn’t seem to have much effect to the SPL readings measured (at ‘milspec-muzzle’) compared with the amount of suppressor section forward of the muzzle. Though the larger expansion chamber areas do help a bit with the pressure for larger volumes of gas associated with longer action cartridges.) In our experience the sound reduction levels of the suppressors with a short muzzle-forward section (4” or less) is usually in the 16 – 23 dB range, and suppressors with a longer muzzle-forward section (6-8”) is usually in the 20 – 32dB range, all depending on the specifics of the make and model of the suppressor in question.

Bear in mind that other factors are at play as well. Shorter barrels WILL BE LOUDER than standard length barrels, and sometimes by a considerable margin. (i.e. in some of our early sound tests with the B&K 2209 meters we checked un-supressed .308win out of 24” barrel at an average of 166.5 dB(A) at milspec-muzzle, and the same (full power, factory high-velocity loads) ammo out of a 16” barrelled .308win gave an average of 169.08 dB(A) !! At 4226.978 Pa (pascals) for the 24” barrels verses 5688.922 Pa for the 16” barrel, that’s a 34.6% INCREASE in the sound pressure level, just due to the reduction in length of the barrel. What this means is that the same suppressor used on either rifle will reduce the noise level peaks by a similar amount, but the shorter barrel will always run about 2.5dB louder (approximately) compared with the longer barrel, all other things being equal.

So while we like 16” or 18” long barrels for our suppressed .308win or other .30cal ‘Kaimai rifles’ that are used a lot with subsonic loads, for other rifles and especially for those that are just used in open country hunting, we tend to recommend customers to leave the barrel as long as possible for their application, up to a point that (when the suppressor is also fitted) it’s not going to be too long or unwieldy. The short answer here is that longer barrels will be quieter, for two reasons:

– firstly that the longer barrel produces a more efficient powder burn and more of the energy is transferred into the projectile in terms of velocity (kinetic energy) rather than being wasted prematurely out of the muzzle.

– secondly is that the further the muzzle/exit point is away from the shooters ear, then the quieter it will also be at that location. This is one of the main reason why (as a gunsmith) I don’t like seeing guys cutting down barrels – especially on magnum rifles – at a length that is far too short, and then fitting a suppressor to them. Not only is this very hard on the suppressor, but you are just wasting a lot of energy/powder out the muzzle and defeating the purpose of having a magnum cartridge to start with in the first place.

Our sound test fixture and setup:

In 2020 and 2021 we designed and manufactured an adjustable stainless steel mounting fixture, specifically intended to securely mount the special sound-test microphones at the specific locations in accordance with Mil-Std-1474D (both ‘1-metre left’ and ‘1-metre right’ of the muzzle at 90-degree incidence, and 1.6m above the ground) and with a flexible elastic-cord to act as a reference position to touch against the front face of the suppressor, or to align with the bare muzzle. There is also an option to mount separate microphones for ‘shooters ear left’ and ‘shooters ear right’. While this is not so precisely specified in the standard, but we use 45” and 9” (i.e. 45” / 1150mm back from the muzzle reference location of the elastic cord, and 9” / 225mm either left or right of the fixture centerline (which is also the centerline of the rifle barrel/bore). Instead of shifting the location of the ‘at ear’ mics to record at the actual ear location each time a different suppressor is fitted to the rifle barrel (thus getting a different distance measurement from the muzzle datum point on the fixture), we prefer instead to maintain the same location for the ‘at ear’ mics whenever doing comparison tests, as this maintaining of a fixed location for the mics promotes a fairer and more honest assessment of comparison tests. The 45” distance tends to line up exactly to where the shooters ear is located with a 24” barrel is fitted with a 6.5” muzzle forward suppressor, which is usually about the longest practical distance for most hunting rifle set-ups.

With this setup and running four B&K2209 milspec sound meters at the same time, we can get readings for ‘Milspec muzzle’ left and right, and ‘Shooters ear’ left and right for every single shot fired. (The meters then have to be manually reset after each shot.) To the best of my knowledge this is currently the best suppressor sound testing set-up available in this country. I am aware of guys running up to 2 meters at once, but no-one has done 4 at once before.

The old analogue Bruel & Kjaer meters have been a mainstay of the suppressor testing industry for the past 40 years, and they are still one of the few portable sound meters available that are capable of recording peak sound level with a fast response time of less than 20 microseconds. This is vital to be able to capture the actual true peak of the gunshot sound/pressure impulse. Anything slower than this does not meet the spec, and cannot be trusted for accurate results.

Sample readings (per calibre tested):

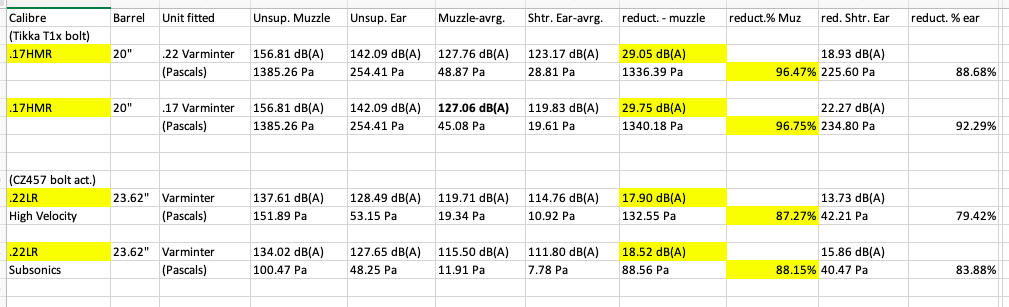

Varminter with 17HMR and 22LR

Explanation of Sound Test Results

In the test data above we used a .17 HMR rifle with 20″ barrel, fired 6 shots unsuppressed, 6 shots with a varminter suppressor with ’17cal’ baffles installed, and 6 shots with a varminter suppressor with ’22cal’ baflles installed. The averages of those shots (and also combined the left and right ‘muzzle’ and the left and right ‘shooters ear’) are listed above.

The interesting thing here is that you can see the ‘milspec muzzle’ readings for both the ’17cal’ and ’22cal’ baffled suppressors are about the same – just over 127dB, but the ‘at ear’ readings are different by about 3.34dB, which is significant. Remember this is the exact same ammo used, on the same day, same rifle, just different clearance hole sizes on the suppressors used.

What is actually happening here is that the sound meter/mic is picking up the sonic crack of the bullet, which in this case appears to be right on the 127.06 dB mark, as being the highest (peak) noise at that location. From the results, and you can safely assume from calculations, that the actual suppressor/gas noise from the ’17cal’ baffles suppressor is more likely to be about 124.42dB. (which would essentially mean a dB reduction at the muzzle (due to the suppressor) of about 32.39dB, which is a good and solid amount of sound pressure peak reduction of about 97.6%). To prove this we would need to repeat these tests with a laboratory-grade system (like the B&K ‘Pulse’ system), but the American test data we have seen confirms this phenomenon where – once you get to the point of extreme sound suppression for a specific calibre – you have recorded sound peaks for the sonic crack of the bullet itself, which can be higher and different than the peaks for the actual gas noise from the suppressor.

This video from YouTube explains and shows their graph example of the sonic crack peaks in relation to the gas noise peaks, which is good to see. However, when they talk about deliberately manipulating data to remove bits that they don’t think are relevant, this can raise ethical issues about what you trying to do or convey. In the real world the sonic crack peak is still there, so if that is the loudest noise then that’s what it is. This does show you however that when you get big enough or effective enough with suppressors, that there is a point of diminishing returns, and there is no point making the suppressor any bigger, longer, or heavier than is required. (This is one reason why full-length over-barrel suppressors have fallen out of favour now.)

Note also that with some subsonic bullets of .30cal or larger diameter, the pressure spike (‘Schlieren’ effect) off the bullet ogive is picked up by the ‘milspec muzzle’ mics – even at subsonic velocities – and this is why with the .30cal and larger subsonics the muzzle readings may not get below approximately 126dB, whereas with the ‘at ear’ readings you will see more of a realistic representation of the performance of the suppressor.

Links/additional info:

LINK: for info about ‘A-weighting’, etc. :- https://www.sciencedirect.com/topics/engineering/a-weighting

Link for Mil-Std 1474D :- https://denix.osd.mil/soh/references/military-standards/mil-std-1474d-noise-limits/

Link to Bullet Schlieren video: https://www.youtube.com/watch?v=BPwdlEgLn5Q

Link to dB to pascals (pressure) converter: https://www.translatorscafe.com/unit-converter/en-US/sound-pressure-level/2-9/pascal-sound%20pressure%20level%20in%20decibels/#:~:text=Sound%20pressure%20level%20Lp,20%20%CE%BCPa%20or%200.00002%20Pa).

Link to typical noise levels of various firearms: (PDF saved in folder) Microsoft Word – Peak dB SPL of Firearms_Lankford 2014 (04072021)